Only sand meeting high specifications can be used as frac sand for hydraulic fracturing (“fracking”).

First, the sand must be of a specific size. Popular frac sand sizes are 20/40, 30/50, and 40/70.

The size of the sand can be determined by performing a sieve analysis.

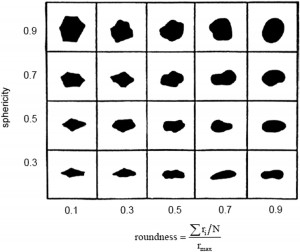

Next, the sand must be of specific shape. The ideal shape for frac sand is a perfect circle, with no sharp edges. If there are any edges, ideally they are rounded, not angular.

Shape of frac sand is determined by the sphericity and roundness test. This test is performed by viewing individual sand particles under a microscope and then comparing them to a Krumbein and Sloss chart.

Each sand particle is rated on how well it conforms to the ideal frac sand shape of perfectly round and spherical.

The sand must be pure to be used for frac sand. This can be determined through turbidity testing and an acid solubility test.

If the sand has lots of impurities, then the turbidity and acid test results will be poor.

Frac sand needs to be very strong. Strength is found using the crush resistance test. The crush resistance test is used to determine a “K Value,” which is the pressure at which 10% or more of the sand starts to break into fines.

High quality frac sand often has K values of 5K, 8K, 9K. Resin coated frac sand and ceramic proppants have even higher K values.

The book “Finding Frac Sand” goes into further detail on how sand is tested and what to look for if you are exploring for sand.

In the book you will find discussion geared toward the frac sand explorer.

This short but informative book includes discussion on sieve analysis, sphericity and roundness testing, acid solubility testing, turbidity testing, bulk density, and crush resistance tests.

A complimentary copy is available here.